One of the critical components in designing electronic products is the printed circuit board or PCB. This board serves to connect various elements of an electronic device and helps them function as a whole. It's a hell of a job to make one good pcb. It includes planning, manufacturing and the assembly of the board. Companies like Engine are experts in fabricating such PCBs, and assist many companies to bring their electronic products to market. The stakes in getting these boards right are high, because if they don’t work, the entire product can fail. Knowing how to locate and select the proper partners is absolutely critical for a lot of developers.

Where to Source Trustworthy PCB Manufacturers for Wholesale Orders?

It can be difficult to find the best PCB manufacturer. Some people search online for them, but you really want to do a little bit of homework. Begin by looking for manufacturers that explicitly state they fabricate PCBs. It's always a good idea to read some reviews before doing anything. On some websites, customers are able to leave feedback. Pay attention to comments about quality, price and delivery time. If you’re on a time crunch, then maybe a fast shipping company is going to be really helpful. Attend trade shows, if possible. These may feature multiple manufacturers and allow you to speak with them in person. A relationship can help down the road, especially with large orders. It can also generate good potential ties with individuals who may have some nice tips. Another process of getting good manufacturers is by inquiring from other business people. They can provide opinions and perhaps refer you to someone they trust. Don’t forget to ensure that the manufacturers observe proper rules and safety standards. That is necessary to check if the custom pcb fabrication are safe for use. If you’re ordering PCBs in large quantities, reach out to the company and discuss what you need. Asking questions can help clear up any doubts. For instance, inquire about how they produce their boards. Do they have the most advanced technology? Are there any quality control measures in place? A reputable manufacturer, such as Engine (or any of the others), shouldn't have much to hide about their procedures. And if you find a manufacturer that seems promising, do not hesitate to ask for samples. Laying eyes and hands on the product can take away any doubts. It demonstrates what you can get, and that’s also big when making a decision.

A Guide to Selecting the Right PCB Fabrication Shop for Your Projects

Selecting the right PCB fabrication partner is crucial to your project’s success. It has little to do with price, but casts the net wide for plenty else. Start by figuring out what you want. What kind of project do you work on? If it’s a custom design at all verify with your partner that they can handle those custom pcb design. Engine, for example, can help out with custom design and support a project from inception to completion. Evaluate the technology they use. A good partner should have relatively new equipment to manufacture high quality boards. Be sure to ask them how they keep up with new developments in technology. Make sure to also review their experience. A business with many years of experience under its belt typically knows how to handle hiccups that arise. Don't ignore communication either. You need a partner who listens, and answers your questions in a timely manner. The reach on them is amazing, if they’re hard to reach you could be in hot water with your cut. An open line of communication is the most essential thing to have in any relationship. Also consider their customer service. A quality fabricator will continue to have assistance available after the boards are fabricated. If you have complications further down the line, you want someone who can help. Investigate their lead times — how quickly can they get your order out to you? If the PCB has to be done fast, make that at priority in your selection. Finally, see if they have a good return policy. This step insulates you in case something goes wrong so it can’t be too late for a refund or replacement. Having this knowledge already under your belt will enable you to choose a partner who matches what you desire, and make the whole process simpler and more successful.

What are the Current PCB Trends for Fabrication and Assembly?

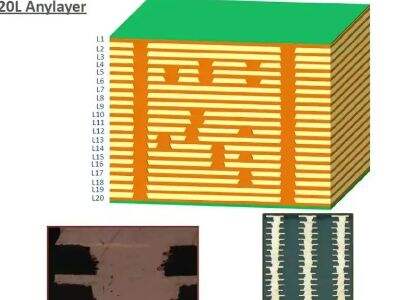

Technology is constantly changing in the modern world. The way we make printed circuit boards (PCBs) is doing that too. The big trend is performance going up by use of advanced materials. For instance, companies such as Engine are developing new types of materials that can enable designs in which PCBs are even thinner and more flexible. This is good, because it makes gadgets lighter and means they can fit in tighter spaces. Another is the trend of automation in PCB manufacturing and assembly. Machines which can insert and solder parts exactly and at high speed are much in demand. This helps it to make more PCs in less time, which is especially crucial when tons of folks demand new computers.

And not to mention, sustainability is a thing now. An increasing number of businesses are trying to be kinder to the planet. Engine is at the forefront of this movement by utilising sustainable materials and processes to manufacture PCBs. Not only does that benefit the planet, it can also draw customers who want to do business with responsible companies. The rise of smart manufacturing is also stake. With the use of data and technology, companies can track how their PCBs are manufactured, so that if something goes wrong, they can identify it and respond quickly. The result is higher quality and efficiency, which in turn translates to shorter time-to-market without compromising the quality of products. New design software is also enabling engineers to design PCBs that are easier to assemble. These programs can even predict problems far in advance and ensure that production rolls smoothly. Together, all of these developments suggest the PCB fabrication and assembly is exciting right now. Thanks to companies like Engine, electronic products are going to continue to only get better.

How to Slash Your Costs with Wholesale PCB Production?

Making PCBs is often costly. But companies like EnginePCB have a solution to help you save money, via wholesale PCB manufacturing. As with any product, when you puchase PCBs in volume units they get cheaper. That’s because the more they produce, companies can also do a better job of scaling resources and spreading out costs. Imagine the difference between buying just one toy or, you know, a whole bunch. The, uh, quantity discount? The more you buy, the less each one costs? It’s the same principle behind PCBs. You can save a lot by simply ordering more.

A great way to minimize your costs even more is to carefully plan out your design. Before you even buy your PCBs sit down and think hard about the design. The design clear and simple, will be manufactured less complicated. If you have lots of complicated designs and features, then it could be more expensive to put together. At Engine, we keep the most streamlined designs as possible and maintain standard sizes and shapes, since typically these will be less expensive to have manufactured. And more, by working closely with the factory that will be building your PCBs, you can also have their input on even-more-cost-effective ways of doing what you do. They might recommend simpler amenities or other materials that allow you to cut costs while maintaining the integrity of your space.

Also, as tempting as it might be to go with the lowest cost option available, quality is obviously also a concern. Sometimes investing a bit more money into higher-quality PCBs keeps you from spending even more later when they fail. This is less maintenance or replacement. Additionally, you should also cultivate existing relationships with your PCB suppliers. If you do, there’s a good chance they’ll give you discounts on future orders or come through when you need to make changes fast. Apply these suggestions in full, and wholesale PCB manufacturing can be a cost-effective decision for your company.

PCB Assembly Mistakes to avoid in the Manufacturing for New Product Development

When creating PCBs for new product there are a few errors people commonly make. Some mistakes can be both a time and or money saver. One of the common mistakes is neglecting to double-check the design before transferring it into production. The specifics must be right and it has to work. A small error in the design can lead to large problems later. We always say at Engine to go slow in the design phase and if you can, get input from other people. This has helped catch errors before they become pricey errors.

Another common mistake is to forget about the board systematic construction when designing the PCB. Some might seem like good designs on paper but extremely difficult or costly to construct. Consider how you want to arrange things on the board and how they will interconnect. If you have a complex design with numerous small parts, the assembly and part costs will go up. Another mistake is not testing PCBs before they are incorporated into the finished product. Testing ensures everything works the way you want it to. And if you don’t do this step, you might end up launching with issues and that could damage the image of your business.

Table of Contents

- Where to Source Trustworthy PCB Manufacturers for Wholesale Orders?

- A Guide to Selecting the Right PCB Fabrication Shop for Your Projects

- What are the Current PCB Trends for Fabrication and Assembly?

- How to Slash Your Costs with Wholesale PCB Production?

- PCB Assembly Mistakes to avoid in the Manufacturing for New Product Development

EN

EN

FR

FR

ES

ES

PT

PT

AR

AR

RU

RU

KO

KO

JA

JA

DE

DE

NL

NL

VI

VI

BG

BG

HR

HR

CS

CS

DA

DA

FI

FI

EL

EL

HI

HI

IT

IT

NO

NO

PL

PL

RO

RO

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

HY

HY

LA

LA

UK

UK