PCBs are all around us! They are essential components of many electronics, including gadgets like smartphones and computers, as well as household appliances. We are not just home to any PCB, but some great custom PCBs that ensure these devices function as they should. But how exactly do manufacturers of these PCB boards create them? Here’s a guide in three simple steps.

What Are The Important Process Steps That PCB Board Manufacturers Take to Make Quality Printed Circuit Boards?

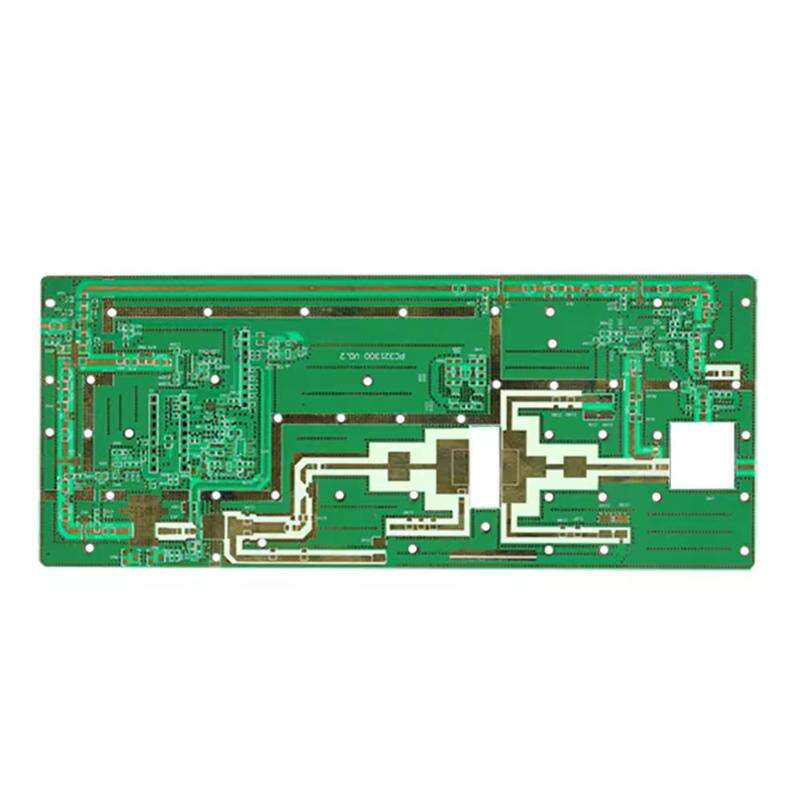

PCB manufacturing process is a complex process and it has many detailed steps. Design phase The first one which is really super critical. On a computer, engineers design a layout for the circuit. This layout has complete routing of electrical lines. When the design is complete, it undergoes a process known as photo lithography. In this, a unique film is generated which facilitates in transferring the design to the PCB material.

Then the boards are cut to the appropriate size by manufacturers. One can do this with lasers or other cutting machines. The boards are washed to clean away any dust or chemicals that have been cut. It’s essential that the PCB circuit board are clean in order to prevent trouble down the line.

Then, layers are added. A single PCB can contain many layers of circuits, connected by tiny holes called Vias. These Vias create many electrical paths. After the layers are stacked, they are soldered together. During production, small components such as resistors and capacitors are mounted on the PCB using interfacing machines. Subsequently heat is employed to the same components to mount them correctly on the board.

Last, each PCB is tested. This may be inspected for any incorrect connections or components. If all goes well, the boards are packed and shipped to customers. We take that process here at Engine really slow and with a lot of care. It enables us to make boards that electronics manufacturers can rely on.

What Are the Benefits of Working with Experienced PCB Manufacturers?

Selecting the best PCB manufacturer makes a huge difference. There are multiple benefits to working with experienced manufacturers such as Engine. For one thing, they know what they are doing. They have been around the block and have taken lessons from the realities of life. This assistance can help them to overcome mistakes and develop the quality.

Another big advantage is efficiency. Professionals have the ability to work faster without compromising the quality. They have their systems finely tuned, so they make PCBs faster. This is especially crucial for businesses that require PCBs to be turned around quickly for their products.

In addition, many established manufacturers employ the latest technology. They spend their money on new machines and software that can enable them to produce a better quality product. This state-of-the-art tech results in PCBs that work better, last longer, and can be tasked with more.

And then there is support, a reason to continue working with a manufacturer you can trust. Which or whatever, its crossed a line into which territory. (Experienced producers know how to talk straight.) And if there are questions or problems, they support their customers. This strong connection can become a defining factor in the success of a project.

Finally, if manufacturers are very familiar with the industry they may have excellent advice. They’ll get help picking the right materials and designs for their needs, to ensure everything works well together. At Engine, we're big on establishing relationships with our clients and to assist in their overall success. Together we can make some really cool things.

What Are Some Common Problems In Using Pcb Board Manufacturers To Produce The Circuit Board?

There are many challenges to manufacturing printed circuit boards (PCBs), as Engine helps explain. One (of the many) problems that crop up is how to design a board that has enough space for all the electrical bits and wires. If the design is flawed, it can cause issues such as short circuits or weak connections. To avoid the latter, engineers thoroughly plan their designs and verify them before they begin production. They have special software that simulates how the board will function. That allows them to catch mistakes early.

Another concern is regarding PCBs' material composition. The materials need to be strong enough to bear the weight of electronic parts, said Boxall, but light so the board is easy to handle. Manufacturers delicately select say the right kind of plastic and metal. If they use the wrong materials, the board can break or not perform well. Engine will always test materials before they even think of going into production. This testing may involve bending the materials to test their strength and probing them for their electrical properties.

Temperature is also an issue that PCB fabricators face. When electronic components perform, they generate heat, and too much of it can fry the board. To counteract this, the boards are made with heat sinks or vents that let the heat out. Engine processes the production to ensure that these features exist. They also measure how much heat the board can withstand before it exposes itself to danger during use.

Finally, quality assurance is a huge consideration for PCB fabricators. After the boards are fabricated, they should be scrutinized for any errors. This could be bad connections or parts that didn’t solder well. Engineers work hard at Engine to ensure all the boards meet a high level of quality. That includes running tests that measure how well the board works before it leaves the factory. Engine can generate reliable printed circuit board by addressing these common problems.

How do You Make Your PCBs Perform and Last Long?

Optimizing PCBs is crucial to making them work better and last longer. Good place to start: Zero in on the design. Engine’s engineers are building models with sophisticated software tools to be more efficient. This is because they design the electronic components in such a way to make them closer to each other. The shorter that distance, the faster and more consistent signals can travel, which is crucial for smooth performance.

Apart from the hardware design itself, selecting appropriate materials is key for PCB optimisation. Some materials are more heat resistant than others. Using materials that do not retain heat is one way manufacturers like Engine can stave off the damage overheat charging can cause. So the board will behave well even in harsh conditions. They select thicker copper for electricity paths to increase the flow of power while avoiding a loss of power.

Size is another important factor for optimization. PCBs that are smaller, for example, can be useful because they save space. However, if too small it can potentially become overcrowded which can pose risks for short circuits. Engine gets it just right by trading scale for breathing room between parts. To do so, they generally employ creative layout tricks designed to make the most of every inch without sacrificing safety or usability factors.

Lastly, another big part of how Engine optimizes its PCBs is through testing and feedback. They then perform a range of tests to see how well they work. They look for any weak spots, or where the board could fail. There's no guarantee it will turn out, but they can use the results to adjust things for their next batch. Ongoing feedback allows them to make refinements to their design and materials, so they perform even better in the future. With a focus in these areas, Engine caters to the printed circuit boards that not only high-performance but also are reliable for everyday use.

Which Innovative Techniques Are PCB Manufacturers Using to Increase Production Rate?

PCB fabricators always want to find some ways to work faster and smarter. At Engine, they utilize a variety of cutting-edge technologies to increase the efficiency of production. Automation is one of the technologies. Automation is a mechanical means of performing dull functions say, soldering or drilling by machines. That means workers can spend more time doing what humans do best, instead of dealing with mundane efforts. Automation also results in fewer errors, which are prone to occur when people are tired or distracted.

Another additional technology is 3D printing which is gaining popularity in PCB manufacturing. Instead of building a board the old-fashioned way, layer by painstaking layer, 3D printing allows manufacturers to rapidly prototype. 3D printing helps Engine try out new designs. This enables them to judge how a design performs in the real world, before they build too many circuit board. Not to mention saving time and money in not having to wait for traditional tools and parts.

Smart software is also reshaping how PCBs are produced. Engine relies on software that can anticipate which machines are likely to fail or require maintenance. This is called predictive maintenance. With this software they are able to identify the spot and solve the problem before it disrupts their operations. This ensures the production process continues smoothly and keeps them on target with deadlines.

Last but not least, data analytics helps in production efficiency too. By looking at data from the production process, Engine can identify where they can do better. They might discover, for instance, which parts they have that take too long to manufacture or which materials tend to lead to delays. Armed with this, they can use it make changes to the system that would simplify the process. All of these advanced technologies are the tools that help Engine create printed circuit boards more quickly and efficiently while maintaining high quality for their customers.

Table of Contents

- What Are The Important Process Steps That PCB Board Manufacturers Take to Make Quality Printed Circuit Boards?

- What Are the Benefits of Working with Experienced PCB Manufacturers?

- What Are Some Common Problems In Using Pcb Board Manufacturers To Produce The Circuit Board?

- How do You Make Your PCBs Perform and Last Long?

- Which Innovative Techniques Are PCB Manufacturers Using to Increase Production Rate?

EN

EN

FR

FR

ES

ES

PT

PT

AR

AR

RU

RU

KO

KO

JA

JA

DE

DE

NL

NL

VI

VI

BG

BG

HR

HR

CS

CS

DA

DA

FI

FI

EL

EL

HI

HI

IT

IT

NO

NO

PL

PL

RO

RO

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

HY

HY

LA

LA

UK

UK