Description:

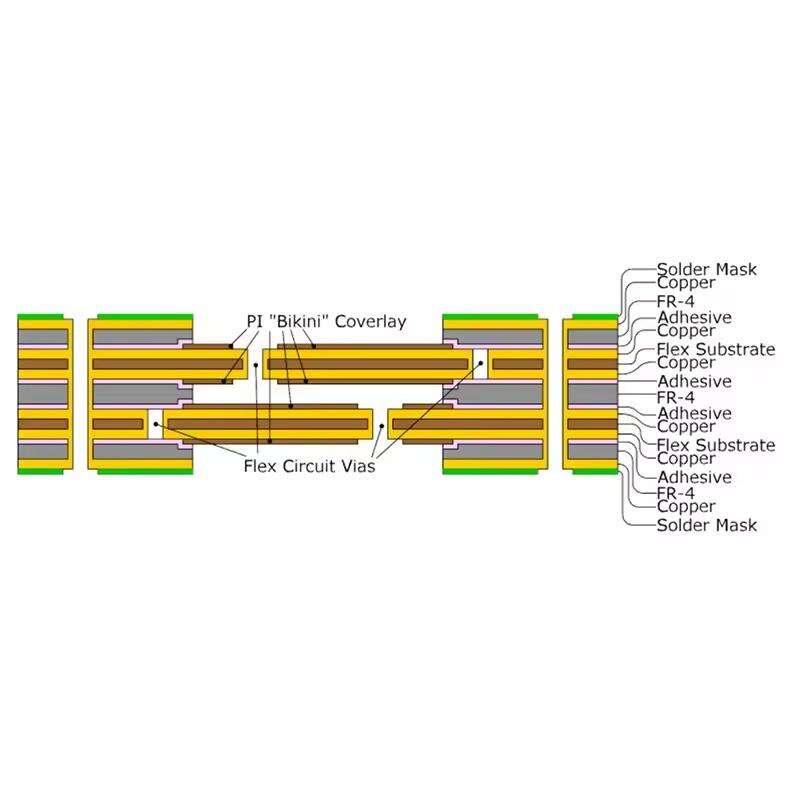

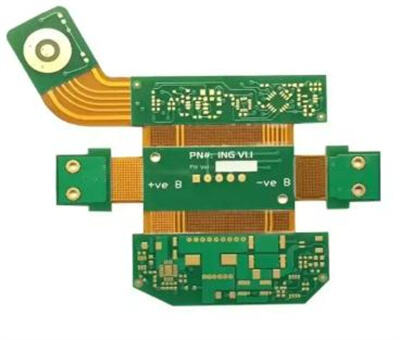

Rigid-flex is especially valuable in applications where space is limited, weight is a constraint, or electronics are subject to mechanical motion. These designs eliminate the need for bulky connectors and cables between rigid boards, improving durability and reducing assembly complexity.

Applications:

Small size, high reliability, and suitable for complex structural designs; main application areas: consumer and BMS, Automated equipment.

Specifications:

| Feature | Capability | Process Capability | Standard | Speciation |

| Layer | 26L | Min.Trace Width/Space | 3mil | 2mil |

| Min. Track/Spacing | 0.065 mm/0.065 mm | Hole size(drilling) | Φ6mil | Φ2mil(laser) |

| Min. Hole/pa Size | 0.10/0.35 mm | Hole size(punching) | Φ20mil | Φ20mil |

| Rigid-Flex Thickness | 0.25-6.0mm | Min. via hole ring | Φ6mil | Φ5mil |

| MAX CU Thickness | 4 OZ | Aspect ratio limits(through holes) | 8:1 | 10:1 (hole size≧D0.30mm) |

| Drilling accuracy | +/-0.05 mm | Aspect ratio limits(blind holes) | 1:1 | 1:1 |

| PTH diameter tolerance | +/-0.05 mm | Layer registration | ±3mils | ±2mils (LDI) |

| MAX WPNL SIZE | 620 mm × 500 mm | |||

| Finish copper (Flex Part) | 0.5-2oz | |||

| Finish copper (Rigid Part) | 1-4oz | |||

| Surface treatment |

ENIG, Electric gold, IM-Ag, Electric Ag, HASL, HASL-LF, IM-Sn, Electric Sn, OSP, Caborn, Pt, NI-Pd-AU |

|||

| Max board thickness: PTH diameter | 13:1 | |||

| Build time | 7-20 days | |||

| RFQ | 1-2 days |

Competitive Advantage:

The versatility of rigid-flex circuit board layouts enables complex and innovative designs that can adapt to non-planar surfaces and accommodate unique geometric shapes, thus pushing the boundaries of electronic device design. The adoption of rigid-flex PCB technology can contribute to more sustainable and environmentally friendly electronic devices by reducing material waste and promoting energy-efficient designs. while rigid circuit areas provide stability and strength for other areas of the product that need increased durability and shock absorption.